Erosion

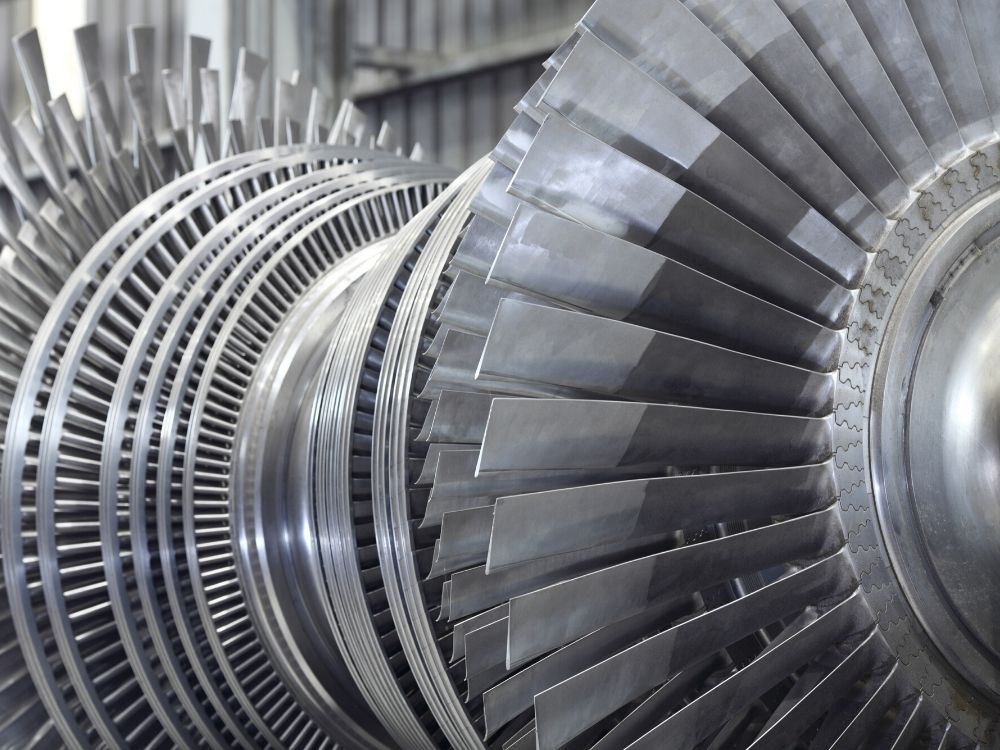

First, moving particles naturally induce gradual changes as they contact turbine components, carrying away bits of their surfaces. These can either be part of the turbine system, such as water in the NOx process, or originate from outside. This slow-going erosive process can induce larger-scale rotor imbalances and other issues. It’s also vital to understand that erosion is a physical or mechanical process; this does not speak to chemical changes within a turbine.

Corrosion

Chemical reactions within your turbine’s inlet, combustion, and exhaust points fall under the category of corrosion. Often, in the presence of outside substances and water, metal corrodes. This is a permanent change that threatens the integrity of your turbine parts.

A key form of corrosion occurs through oxidation. This is the process that turns copper metal green, most well known from the gradually greening color of the Statue of Liberty. You can mitigate corrosion by cutting down on contaminants that take part in these corrosive reactions, two of which are sodium chloride and sulfur. To further protect your turbine, you can perform cleanings that rid it of lingering substances.

Temperature-Based Issues

Temperature-based failings are another class of things that can go wrong with your gas turbine. Sometimes, residual or leaking fluids can suddenly freeze up in wintertime. This causes ice to expand outward and disrupt various components.

Alternately, exhaust heat expands and strains your pipe system. Pipes have measures in place to redirect and manage thermal expansion, but over time even these measures can fail. For example, pipe expansion joints face several challenges that can compromise their ability to accommodate expansion. Preemptively inspect and maintain your entire pipe system to avoid leaks and cracks that can worsen when temperatures grow hot or cold.