Develop a maintenance and inspection schedule

If your current maintenance strategy involves neglecting the motor until something goes wrong, your motor will never last. Instead, you should put a maintenance schedule in place that will hold yourself and others accountable. Most manufacturers suggest inspecting your motor at least weekly; all things considered, though, you simply want to keep an eye on the motor, which leads us to our next point.

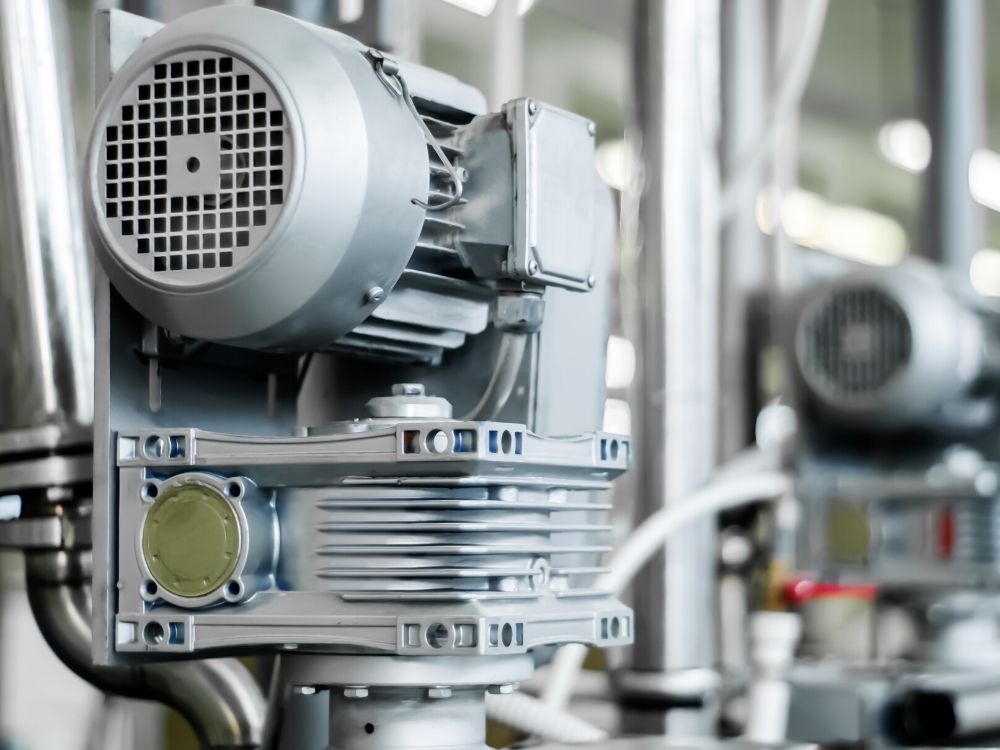

Perform visual inspections

While it sounds simple, regular visual inspections can help you detect and avoid the common reasons electric motors fail. You should always keep an eye on the motor’s vents because a motor’s worst nightmare is dust and debris. If dust builds up and finds its way into the motor, it’ll wreak havoc and likely cause overheating. In other words, clean your motors—luckily, it’s not hard.

Run vibration tests

Another way you can ensure better electric motor maintenance is by performing vibration tests. Every motor—whether it’s electric or no—will vibrate to some extent. However, the motor shouldn’t be moving uncontrollably. There are numerous ways to test a motor’s vibration; one simple way involves removing the motor’s belts and seeing if it’s still unstable. If the motor still vibrates excessively after detaching the belts, the motor probably needs an alignment or new bearings.

Industrial industries rely heavily on machinery, but that machinery is often powered by an electric motor. If you fail to maintain your equipment’s motor, you’re not only hurting your investment, but your business will experience downtime more frequently. You can avoid wasting time and money by merely implementing this guide into your business’s practices.